PullSystem - system features

What is PullSystem?

It is a parts distribution system for production lines.

Why PullSystem?

Pull System helps to simplify

and automate the process of handling

orders for components and their delivery.

Where is it worth to implement PullSystem?

At assembly stations in organized

and planned production plants.

System architecture

Central server

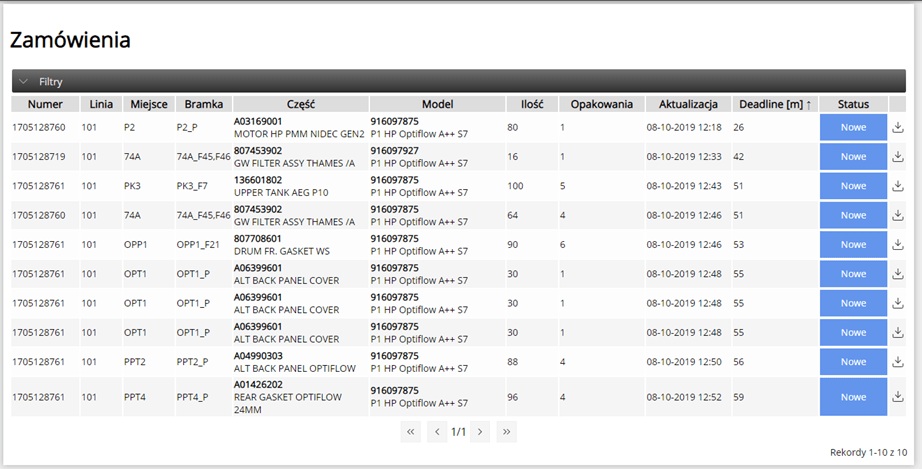

It processes production orders (production plan) from external sources (ERP systems) or defined within the system (administrator application).

It calculates (in real time) the demand of production stations for components (creation of orders).

It generates system messages related to system operation and the appearance of new components for installation.

A special feature of the server is its strong reactivity to external factors (configuration parameters, line corrections). As a result of sudden changes, e.g. in stocks, the system updates the demand and then introduces corrections to orders.

WEB application

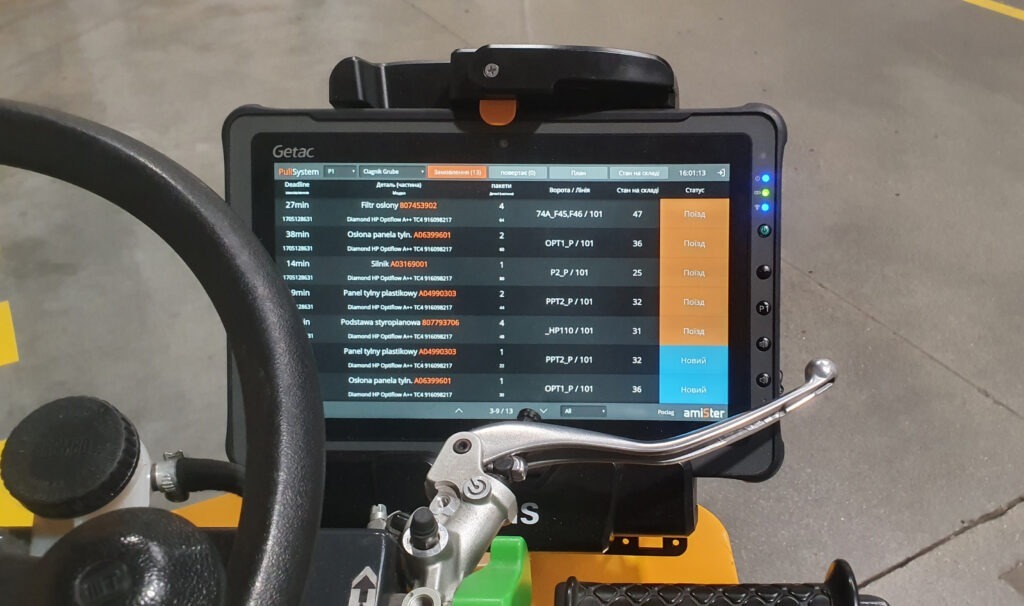

It has many advantages for operators of vehicles transporting components between lines, including:

- friendly, intuitive and multilingual user interface,

- the ability to view production levels on the lines,

- in-system communicator.

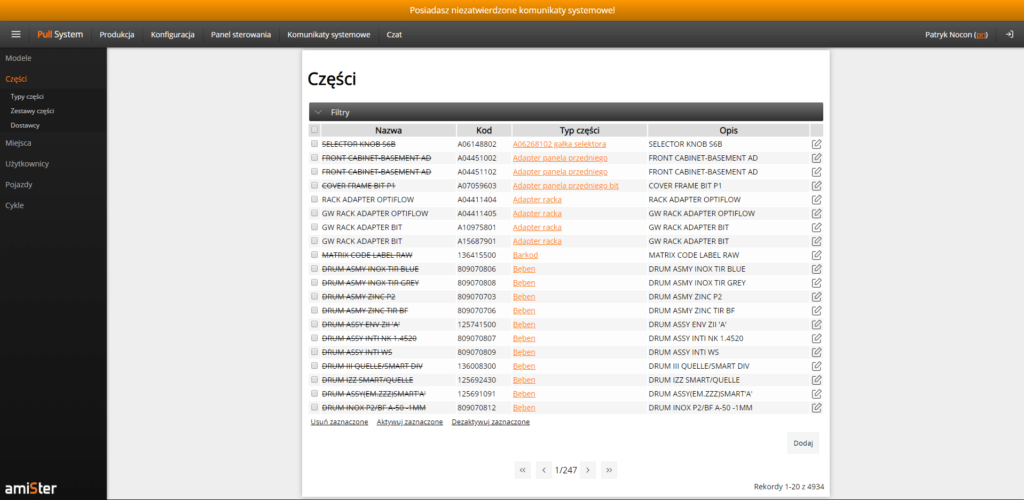

The system administrator is given the ability to parameterize the system and enter certain production data:

- parameterization of server operation (core),

- registration of production data (parts, substitutes, manufacturers),

- adding vehicles and their observation module,

- production statistics module,

- the ability to add employees and an in-system communicator.