QSystem’s main tasks include: constant inventory records and optimal placement of components in the buffer (according to an algorithm adapted to the priorities previously defined by the production plant), issuing components in accordance with LIFO and FIFO, as well as a clear and efficient graphical presentation of the buffer.

The QSystem solution enables integration with other IT systems, e.g. PullSystem, which is responsible for the distribution of components to production lines, in accordance with the “just in time” method.

QSystem architecture

QSystem is a web application operating in the client-server architecture. Thanks to this:

- It is easy to service,

- It enables easy application update, without causing downtime in production (you can “refresh” with one click, you don’t have to restart the application).

- It reduces application maintenance costs (in IT departments).

Application for the operator

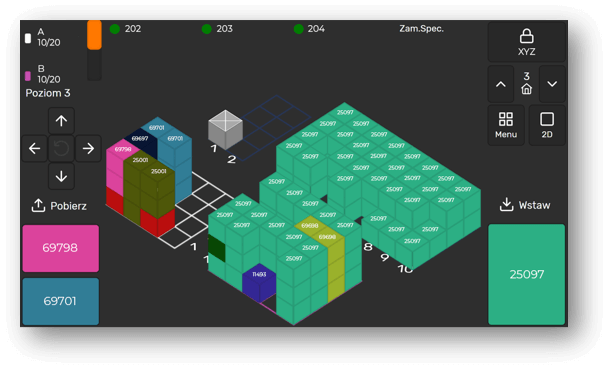

The module for the operator allows you to choose the type of view – 3D or 2D. The 3D view shows the contents of the buffer in an isometric projection and allows its presentation on different levels. The application also allows you to rotate the view, which makes it much easier to view even hard-to-reach locations. While the production buffer in the 2D view is presented “from a bird’s eye view”, the content of one level is always visible. In both views, the user can easily change the level currently displayed on the screen.

QSystem features - operator’s module

| Uploading platforms from the buffer, according to LIFO or FIFO. |

| Inserting platforms into the production buffer. |

| The possibility of placing platforms according to various schemes, e.g. on one or more levels. |

| Placing components in the buffer - according to priorities predetermined by the manufacturing plant. |

| Automatic selection of the location of the platform to be inserted or downloaded - the algorithm analyzes the distribution of platforms and selects the optimal place taking into account all predetermined assumptions (e.g. whether to group platforms with the same components in one channel, when to download incomplete platforms, when to download alternative components, etc.). |

| Ability to manually change the location of the uploaded or downloaded platform. |

| Filtering - efficient finding of a specific component, type of platform. |

| Automatic or manual determination of the number of components to be downloaded. |

| The ability to quickly change the number of components in the platform - by 1.10 or by entering a specific value. |

| Ability to indicate only platforms containing a specific component (preview of components). |

| Possibility of inserting many types of components into one platform (MIX) and NRFT platforms. |

| Quick access buttons, e.g. two recently added components - no need to select a given component from the list each time to download or insert. |

| Automatically assigning components to more than one platform if their number exceeds the default value. |

| Automatic indication of more than one platform if the number of downloaded components exceeded the default value. |

| Ability to undo the last action. |

| East update of the app - no reboot required. |

QSystem facilities — operator’s module

- Clear presentation of the buffer – 3D and 2D view.

- Intuitive operation – large buttons and sliders that allow you to operate the system g. wearing gloves, a large font that makes it easier for people with poor eyesight to read messages.

QSystem functions — Admin’s module

- Creating new areas and their configuration.

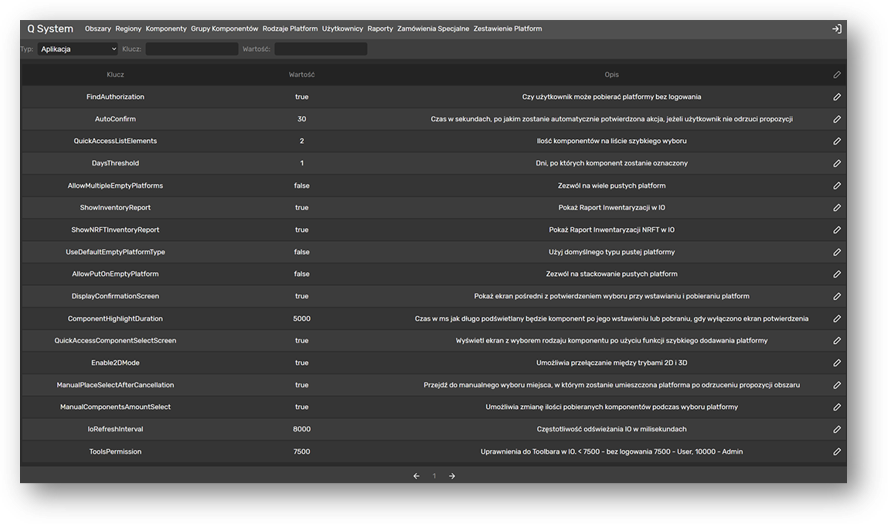

- Ability to configure channels, components and users “from scratch”, the ability to fully edit and delete them.

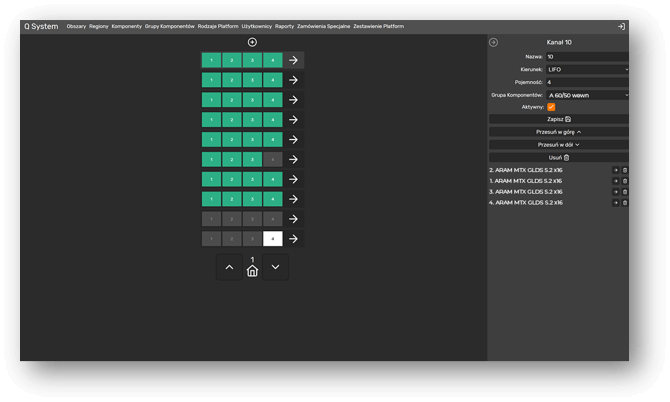

- Configuring channels – incl. order, length, name.

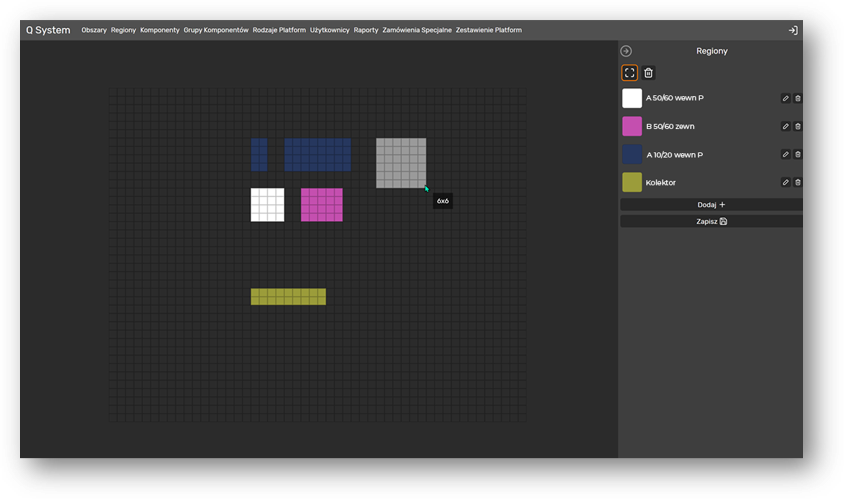

- Creating regions using a graphical editor – the ability to create any shape makes it easier to map the actual appearance of the buffer.

- Assigning colors to regions – this allows you to quickly distinguish them.

- Possibility to specify the direction of entry and exit of regions.

- Defining channels as LIFO, FIFO.

- Creating structures on the plan of buffers, without the possibility of placing components in them – they allow you to mark, for example, pillars or machines, which facilitates orientation in the buffer.

- Ability to specify the maximum height of selected buffer areas or completely block the possibility of stacking platforms on top of each other.

- Granting permissions to users.

- Ability to edit each of the platforms – incl. changing the type of platform, the number of components in it.

- Editing stock levels in the buffer.

- Access to reports, special orders (reservation of specific platforms from the buffer with the possibility of defining the place of their execution – line and station) and platform data.

QSystem — reports

Inventory Report – Contains information on all platforms in the area.

NRFT Inventory Report – Provides information on all NRFT platforms in the area.

User activity report – a summary presenting the daily activity of users. It allows you to verify the performance and check whether the system is properly operated by employees.

“Platform Information” report – contains information about the component included in the given platform, type of platform, as well as location, date of entry and an alternative component.

Why is it worth it?

- Supporting effective management of production buffers, ensuring production continuity and keeping components on time.

- Optimization of released components (components do not queue in the buffer).

- Permanent access to data on the stock level in the buffer.

- High degree of scalability through the ability to configure each of the areas – you will adjust the solution to the specific needs and strategy of your production plant.

- Possibility of integration with other solutions, e.g. with the PullSystem solution.

- Intuitive in use, low cost and a simple way of servicing applications in the client-server architecture.